TOP TRAY

Baumer recently designed and built a shrink-wrapping machine equipped with a particular system inserting a plastic top-tray around the bottles neck. This application is suitable for different types of product and it can pack various configurations (3x2, 4x3, etc…).

This system enables creating multipacks also in double and triple lane without using film. The same machine can then insert the produced multipacks in tray or shrink-wrap them with film only to produce a final packing for palletisation.

TRAY & LID TRAY PACKER

Baumer’s range includes a special system to pack products in tray & lid closed on two or four sides.

This new type of packaging allows saving cardboards and offers the customer the opportunity to display the products in different ways at the dealer’s.

This tray packer can also pack in wrap-around carton and in shrink-wrapping film thus giving the customer the maximum versatility.

STACKING SYSTEM

Baumer provides different types of stacking systems according to the product to be packed:

Stacker for loose products (pots on pots)

Stacker for trays

Stacker for flat boards

The stacking system runs uninterruptedly without stopping the products thus granting higher production speeds and greater reliability.

COMBINER FROM 2 LINES TO 1

Baumer developed a special system to combine the production of two lines into one. This system runs uninterruptedly without stopping the production.

It is suitable for handling any container; in particular, in the Tetra-brick sector it prevents pressure from damaging the product.

This system has been designed to always grant the production also in case one filler does not feed products.

The advantages are:

Using one end of line only for two or more production lines

Room saving in production

Saving on the purchasing of the machines

No pneumatics and control of the products flow through Brushless motors

Possibility to mix different products in the same final packs

QUINCUNX FORMATION DEVICE

All Baumer's machines can install the Quincunx-formation system that allows optimising space for palletisation.

Baumer machines can pack products both in usual configurations and - with some formats - in Quincunx formations.

TAPERED CONTAINERS

This machine is an absolute novelty on the World market and it is the result of Baumer’s continuous research to meet the customers’ need to reduce the production costs.

Baumer’s solution allows the customer to very quickly recover the capital investment due to the elimination of the traditional wrapping in tray and film with a new type of packaging made of special flat board. This line allows saving more than 75% on the costs of raw materials.

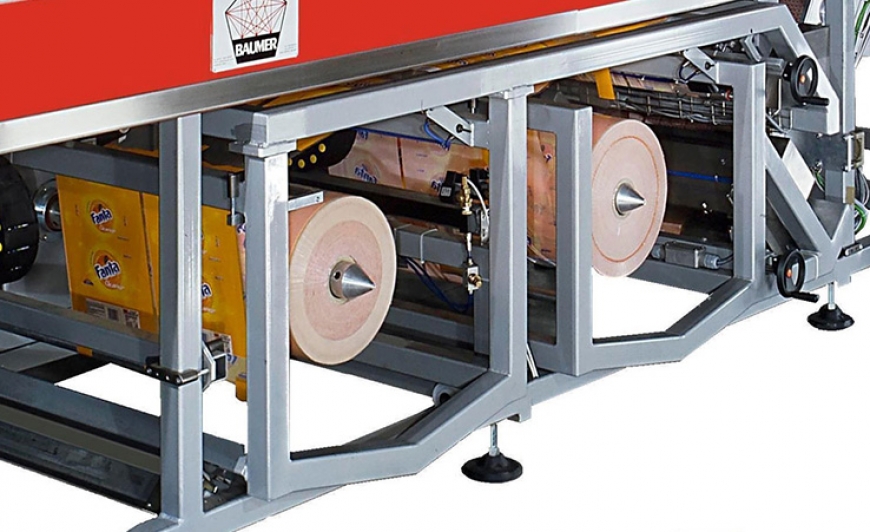

AUTOMATIC REEL CHANGEOVER SYSTEM

This system boasts of five international patents defined as “highly innovative”. This is the only non-stop production system and it enables to automatically change the reel without operator assistance or attendance, with no film welding and at production speed.

The system can work with plain and with pre-printed film and it allows more of 15% saving on raw materials because it works with film reduced in dimension and thickness.

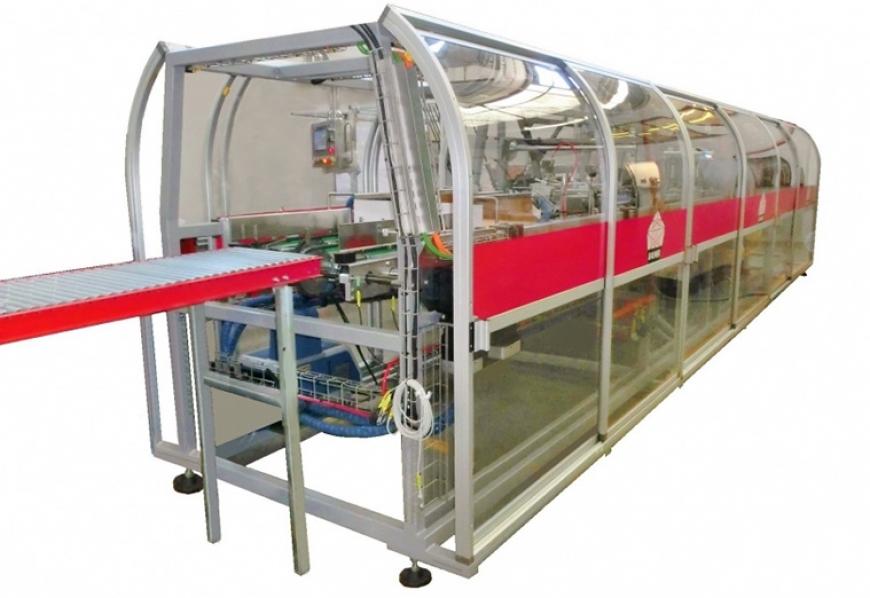

BM BELT SYSTEM

Baumer’s BM BELT patented system allows creating different packaging types with one machine only (e.g. film only, tray and film, flat board and film, and wrap around) in a completely automatic and rapid way.

The system uses a motor-positioned conveyor belt, which is integrated into the machine and whose function is to exclude the chains that transport the cardboard blanks thus enabling to change from wrap around to film only configuration in a very short time. This belt can be completely controlled from the operator panel and it positions automatically during format changeover operations without operator’s intervention.

This system offers the customer a production flexibility that was not possible before.

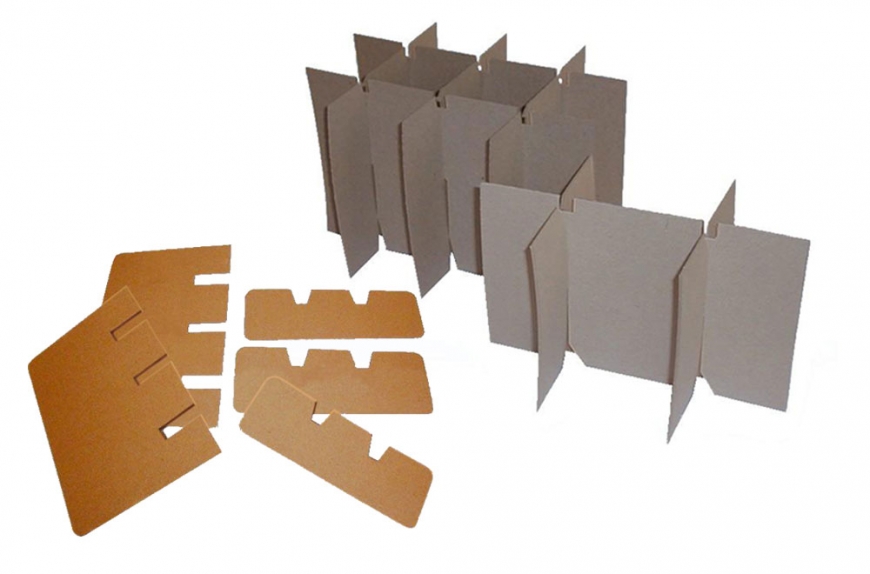

PARTITIONS

Baumer’s Wrap Around cartonning machines can be equipped with a system for the insertion of partitions in order to meet all packaging/shipping requirements. Baumer proposes two systems for partition insertion.

Non-assembled partitions

Baumer has patented an exclusive system of inserting non-assembled partitions from below, which offers the customer various advantages.

Read more- Significant costs savings through the use of simple flat cardboard pads instead of pre-assembled partitions.

- Convenient and safe loading of low level cardboard magazine.

- Production speed of up to 65 cartons per minute.

- The ability to pack products in larger configurations (e.g. 6x4).

- No label damage.

Preformed partitions

Baumer engineers have designed a rotating preformed-partition insertion system enabling the achieving of production speeds twice that of standard robotic solutions.

The partitions are picked up by suction cups and are guided until their insertion among the bottles thus avoiding any label damage.

90° INFEED SYSTEM

This special system allows producing a non-stop movement using a rotating push that, at production speed, guides the products without pressure.

This system is suitable for bricks but can also work with cylindrical, square, rectangular and oval products.

Designed to work at high production speed (up to 24.000 bph) allows having compact lines thanks to the divider elimination.

Traypacker for big formats

Baumer launched on the market the special line Traypacker 1000. The machine can produce traditional formats or work in quincunx collation to insert more products in a tray.

This machine has been developed to produce big size trays, such as:

- ½ industrial pallet (1000x600 mm)

- ½ euro pallet (800x600 mm)

- ¼ euro pallet (600x400 mm)

Traypacker 1000 offers many advantages:

Great reliability:

The packaging process grants the products stability: bottles are conveyed at a constant speed to the collation area. They are then placed on the trays coming from below and closed on the four sides in continuous around the products.

Compact layout:

The machine’s compact dimensions allows its insertion also in reduced spaces.

Innovative displaying system:

Trays can be displayed directly in the store in a quick and easy way. This type of packaging facilitates both salespersons in the arrangement of products and customers in choosing and picking up products.

Are you interested in the catalog? Contact Us